Spotlights

Business Manager, Center Manager, Department Manager, District Manager, General Manager (GM), Operations Director, Operations General Manager (Operations GM), Operations Manager, Plant Superintendent, Store Manager

Think of an organization as an orchestra, where everyone plays a different instrument and part. Without direction, the results can be chaotic – so they need a skilled conductor to bring the players into harmony.

Organizations are the same. They rely on Operations Managers to act as sort of “conductors” who help workers collaborate so processes can go smoothly. Operations Managers are the backbone of a wide range of business types, ranging from manufacturing companies and retail chains to healthcare facilities, distribution centers, banks, and more. They oversee efficient, productive processes across operations such as production and distribution.

Their responsibilities include developing and implementing policies and standard operating procedures, managing day-to-day operations, monitoring maintenance and repairs, and planning the use of materials and human resources. Operations Managers also supervise other managers, uphold quality assurance standards, and create strategies to enhance performance and profitability.

In this role, they juggle multiple tasks and make critical decisions daily, requiring strong leadership and collaboration skills to keep everything running seamlessly!

- Ensuring smooth, efficient operations that boost productivity and worker satisfaction

- Opportunities to work with diverse teams across various departments

- Being at the forefront of solving complex operational challenges

"Keeping up-to-date information as the team grows, and assisting to resolve an issue." - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

Working Schedule

Operations Managers typically work full-time, with the possibility of overtime during busy periods. They may work in various settings, including offices, manufacturing plants, and distribution centers.

Typical Duties

- Write, implement, and enforce policies and procedures to improve operations, reduce inefficiencies, and maintain regulatory compliance

- Establish production goals and other objectives, along with realistic timeframes

- Oversee and coordinate processes related to production, supply chain and distribution activities, sales, and financial tasks such as budgeting, resource allocation, and cost-saving measures

- Monitor performance metrics to identify areas for improvement

- Review projected customer demands. Help establish pricing and credit terms. Execute marketing strategies like sales promotions

- Organize staff schedules and handle certain personnel management duties, such as hiring, training, and giving performance reviews

- Anticipate and mitigate workflow issues by maintaining proper equipment maintenance schedules

- Address production issues immediately to prevent work stoppage. Identify root causes of problems

- Oversee quality assurance and testing procedures

- Develop environmental and sustainability programs to reduce waste and ecological impacts

- Develop and use advanced data analytics tools to optimize supply chains and identify opportunities for operational improvements

- Oversee change management efforts for new technology implementations and process overhauls

- Help optimize processes that impact customer satisfaction, such as order fulfillment, delivery, and returns management

Additional Responsibilities

- Conduct risk assessments and develop crisis management plans for handling emergencies, such as natural disasters, cyber-attacks, or supply chain disruptions

- Work with company training managers to create safe work environments

- Ensure compliance with health and safety regulations by conducting regular audits and implementing corrective actions

- Stay up-to-date with industry trends and best practices

- Negotiate contracts with suppliers and vendors

- Coach junior managers and help them advance their careers

Soft Skills

- Adaptability

- Analytical

- Attention to detail

- Communication

- Conflict resolution

- Critical thinking

- Decision-making

- Leadership

- Motivation

- Organization

- Problem-solving

- Teamwork

- Time management

Technical Skills

- Accounting, budgeting, and financial management programs

- Budget management

- Change management

- Cloud-based data-sharing programs (Google Drive, Slack)

- Contract negotiation and vendor management

- Data analysis and reporting

- Document management

- Enterprise resource planning systems

- Human resources management

- Process mapping

- Production processes

- Project management and software (Monday, Asana)

- Quality control techniques

- Risk assessment and crisis management

- Scheduling and timeline management

- Supply chain management

- Teleconferencing

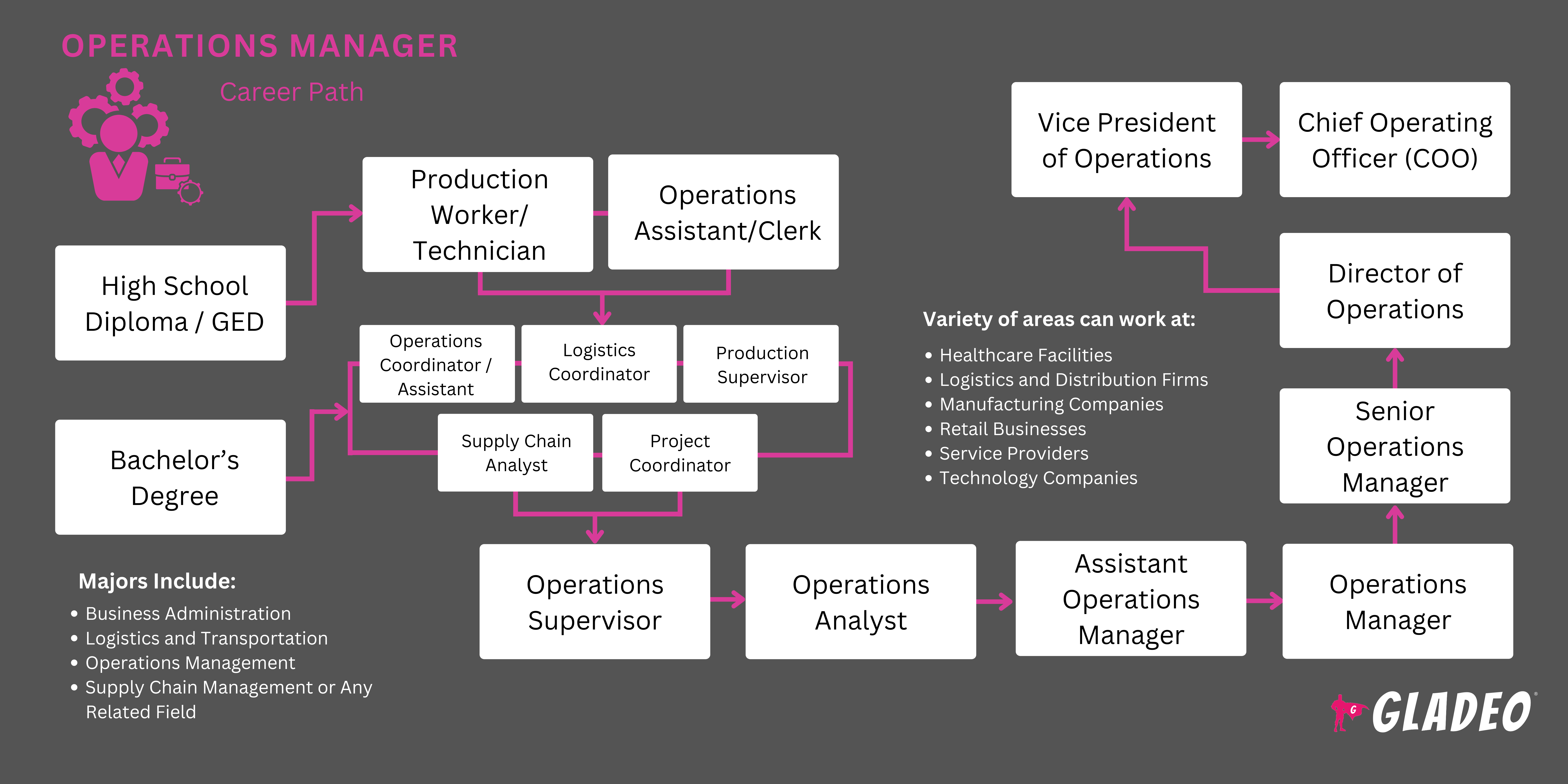

- Healthcare facilities

- Logistics and distribution firms

- Manufacturing companies

- Retail businesses

- Service providers

- Technology companies

"Options are endless! Any team operation—accounting, human resources, reception…" - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

Operations Managers are expected to maintain high standards of efficiency and productivity. The job requires a keen eye for detail and the ability to make quick decisions that may have far-reaching consequences.

They often work under pressure to meet tight deadlines and must be prepared to handle unexpected challenges. Thus, they need strong leadership and teamwork skills, along with a dose of flexibility.

Long hours may be required to address challenges, especially during critical project phases. Despite the job demands, Operational Managers derive satisfaction from making positive impacts on their employer’s organization.

Operations management is evolving with advancements in automation, artificial intelligence (AI), and data analytics. These tools provide real-time insights to enhance decision-making and streamline workflows, leading to better project tracking, resource allocation, and risk management. These advantages help organizations boost productivity and reduce costs.

Meanwhile, agile frameworks are changing operations by fostering collaboration, adaptability, and continuous feedback. By breaking projects into smaller chunks, teams can respond faster to changes and reduce inefficiencies.

Another trend is that organizations are increasingly integrating sustainable and socially responsible practices, such as using renewable energy sources to reduce carbon footprints, minimizing waste, and promoting fair labor practices and safer working conditions.

"To reduce carbon footprints and eliminate R-22 refrigerant." - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

Operations Managers must be very process-oriented and able to elicit the best work out of employees. They may have exhibited natural leadership and management traits as kids, comfortable being in the center of the action. Their parents might have given them chores and responsibilities at an early age, or perhaps they were simply drawn to taking charge of things at school.

Many Operations Managers honed their skills over years, working at early ages in retail stores, warehouses, or other logistics-oriented settings. Some may have also served in military positions, acquiring discipline and a sense of urgency that carried over into their civilian careers.

"For me, it was crafting, organizing, cosplay…" - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

"Mondays are payroll to process. Every business day is sending out the daily work order report to the customer from the previous day. Pay any department payables and submit startup reports. Work on generating the department manual." - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

- In general, there are no mandatory educational requirements for Operations Managers. However, since they can work in numerous sectors, industry-specific education and training could be needed.

- Per O*Net, ~ 29% of Operations Managers have a high school diploma or GED. 22% have some college and 27% have a bachelor’s degree.

- No specific degree major is necessary, but popular options might include business administration, operations management, supply chain management, industrial engineering, management information systems, logistics and transportation, and engineering management.

- Relevant work experience in operations or a related field is usually essential, which is why most Operations Managers work their way up to the position versus starting fresh out of school.

- Professional certifications are optional but can enhance one’s qualifications. Certifications include:

- AACE International - Certified Cost Technician

- American Academy of Project Management - Project Manager E-business

- American Institute for Business Management - Certified Operations Manager

- American Public Power Association - Energy Efficiency Management Certificate Program

- Association for Strategic Planning - Strategic Management Professional

- Association for Supply Chain Management - Certified in Production and Inventory Management

- Institute of Certified E-Commerce Consultants - Project Management E-Business

- Institute of Certified Professional Managers - Certified Manager

- International Facility Management Association - Certified Facility Manager

- National Contract Management Association - Certified Commercial Contracts Manager

- Solid Waste Association of North America - Managing Recycling Systems

- Additional areas for education and training classes may include:

- Learning tools like Microsoft Excel, SQL, or ERP software to analyze complex data sets and make data-driven decisions.

- Project management methodologies like Agile or Lean and certifications such as Project Management Professional.

- Familiarity with automation, artificial intelligence, and machine learning in operations.

- Change management strategies to implement new processes and technologies while minimizing resistance.

- Knowledge of risk management and compliance.

- Financial acumen to manage budgets and perform cost analysis.

"[It takes a ] bachelor's now. Before, just a high school diploma plus relevant experience." - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

- Look for accredited programs offering majors in business administration, operations management, supply chain management, logistics and transportation, engineering management, or other fields related to the specific types of industry you want to work in.

- Seek programs with internships or opportunities to get hands-on practical experience.

- Decide if you want to go to classes in-person, online, or via a hybrid program.

- Compare tuition and fees costs, noting in-state vs. out-of-state costs.

- Review scholarship and financial aid options.

- Check out graduation and job placement statistics.

- Read about the program’s faculty and their accomplishments, as well as the alumni network.

"Learn to multitask! Tunnel vision is not reality. Initiate finding a solution. Try, even if wrong. Always learning!" - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

- In high school, you’ll need to master subjects like business, management, and mathematics. Advanced Placement courses might be a good choice, too.

- To hone your communication skills, take English, writing, speech, and debate.

- If you plan to work in a technical field, sign up for plenty of science, engineering, and technology courses.

- Apply for part-time jobs or internships where you have to manage complex projects.

- Volunteer for extracurricular activities roles to get experience with leadership, management, process coordination, logistics, and budgets.

- Take online courses via edX or Udemy to polish up your skills.

- Read books and articles related to operations management practices and techniques.

- Keep track of work and academic accomplishments for your resume and/or college applications.

- Join student organizations like Future Business Leaders of America.

- Shadow or interview working Operations Managers to gain insights.

- Visit companies that offer free tours of their operations.

- Attend career fairs and industry events to grow your network and learn about career paths.

- To work as an Operations Manager, you may have to start in an entry-level job and get experience first.

- Make a profile on LinkedIn and other networking platforms to advertise your availability.

- Scan job portals like Indeed.com, Glassdoor, ZipRecruiter, USAJOBS, and other sites.

- Review job ads and look for keywords to list on your resume, such as:

- Agile Methodologies

- Budget Management

- Milestone Tracking

- Performance Metrics

- Process Improvement

- Project Planning

- Quality Assurance

- Resource Allocation

- Risk Management

- Schedule Management

- Team Leadership

- Vendor Management

- Workflow Optimization

- Review Operations Manager resume templates for ideas.

- Read sample interview questions such as “How do you handle a situation where a project is falling behind schedule, and what steps do you take to bring it back on track?”

- Practice your replies via mock interviews.

- Stay connected to your professional network. Ask for leads on upcoming job openings.

- Ask former professors and supervisors to write recommendation letters or request their consent to list them as references.

- Keep up with current developments related to the industry you work in. Know the terminology before going into interviews.

- When you get called for an interview, research the organization to learn about their mission and values, so you can speak to them about how well you’ll fit into the work culture.

- Dress appropriately for job interviews!

"Apply yourself, ask others for help, observe and learn." - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

- The best way to move up in an Operations Manager job is to keep employees safe and motivated, ensure processes run smoothly, meet deadlines, stay within budgets, maintain quality control, and comply with regulations.

- Let your supervisor know you’re interested in professional development and career advancement. Offer to take the lead on tough projects. Ask if there’s any additional education and training they recommend for you to increase your value to the organization.

- If you have a bachelor’s, consider knocking out a master’s degree or additional certifications if it’ll help you qualify for promotions or raises.

- For example, if you deal a lot with inventory, consider earning the Association for Supply Chain Management’s Certified in Production and Inventory Management credential!

- Anticipate problems and be proactive in preventing them. When a problem is unavoidable, offer feasible solutions and stay focused on end goals.

- Learn how to manage change effectively so that workers will get on board and not push back.

- Grow your professional network by staying active in organizations like the Association for Operations Management.

- Stay current on regulatory changes to ensure your organization is always compliant.

- Consider relocating or switching employers if necessary to achieve career goals.

Websites

- AACE International

- American Academy of Project Management

- American Concrete Institute

- American Institute for Business Management

- American Management Association

- American Production and Inventory Control Society

- American Public Works Association

- American Welding Society

- Association for Operations Management

- Association for Strategic Planning

- Association for Supply Chain Management

- Council of Supply Chain Management Professionals

- Financial Management Association

- INFORMS Blog

- Institute of Certified E-Commerce Consultants

- Institute of Certified Professional Managers

- Institute of Supply Management

- International Facility Management Association

- Jay, Barry and Chuck's OM Blog

- McKinsey & Company

- Micro Focus Community - IT Operations Management

- National Contract Management Association

- National Management Association

- Project Management Institute

- Public Sector HR Association

- Solid Waste Association of North America

- The Operations Blog

- USC Consulting Group

Books

- Operations and Supply Chain Management Essentials You Always Wanted to Know, by Vibrant Publishers and Ashley McDonough

- Operations Management For Dummies, by Mary Ann Anderson, et. al.

- The AI Revolution: Transforming Operations Management: Shaping the Future of Industry by Unleashing the Power of AI in Operations Management, by Dean H. Stanton

"Cal/OSHA. Join a union trade. Try something new to know if you enjoy it or not.” - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

Operations management can be rewarding but stressful at times. Interestingly, the skills needed to be a successful Operations Manager can apply to countless other professions, too. So if you’re curious about exploring other careers, check out our list below!

- Administrative Services Manager

- Business Analyst

- Computer and Information Systems Manager

- Construction Manager

- Consultant

- Cost Estimator

- Facilities Manager

- First-Line Supervisor

- General and Operations Manager

- Industrial Production Manager

- Logistician

- Market Research Analyst

- Product Manager

- Program Manager

- Project Manager

- Quality Assurance Manager

- Sales Manager

- Supply Chain Manager

- Training and Development Manager

- Transportation, Storage, and Distribution Manager

"It is never too late for a new dream or skill. Knowledge really is power!" - Nicole Kohorts, Service Operations Coordinator at Air Treatment Corporation

Newsfeed

Featured Jobs

Online Courses and Tools

Annual Salary Expectations

New workers start around $65K. Median pay is $101K per year. Highly experienced workers can earn around $160K.